Thermal conductivity k is the quantity of heat transmitted due to an unit temperature gradient in unit time under steady conditions in a direction normal to a surface of the unit area.

Heat transfer coefficient stainless steel tank.

The heat transfer coefficient is the proportionality coefficient between the heat flux and the thermodynamic driving force for the flow of heat i e the temperature difference δt.

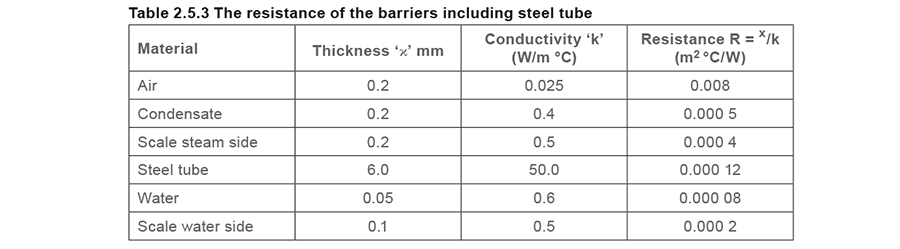

Dt t 1 t 2 temperature difference over wall o c o f the overall heat transfer coefficient for a multi layered wall pipe or heat exchanger with fluid flow on each.

You can model the steel insulation as a single layer of insulation by replacing the steel with a thinner layer of insulation that matches the thermal conductivity of the steel layer.

Heat transfer dimple jacket dimple jacket fabrications welding cmpi provided mechanical dimple jackets are sheets of metal with equally spaced depressions or dimples pressed into the metal to provide contact points for welding to a base such as a tank or pressure vessel.

The heat transfer coefficient you ll just have to dig around on the web.

Calculate conductive heat transfer.

Jacketed vessel heat transfer calculation estimates overall heat transfer coefficient for a vessel with an agitator along with heating cooling medium flowing in jacket spiral jacket or half pipe coil.

Chemical engineering calculations to assist process plant operation and maintenance engineers.

Typical overall heat transfer coefficients u values.

You can calculate it from first principles using the reynolds nusselt and prandtl.

Thermal conductivity k is used in the fourier s equation.

Calculate overall heat transfer coefficient.

Amount of heat required heat flux w m2 i e thermal power per unit area q d dot q da.

Heat transfer through a surface like a wall can be calculated as.

H q ts k where.

Q u a dt 1 where.

Home up back shell tube air coolers immersed coils jacketed vessels.

Search is the most efficient way to navigate the engineering toolbox.

A wall area m 2 ft 2.

Heat transfer in agitated vessels can be carried out either through an external jacket on the vessel or by internal coils where a jacket or coils cannot provide the surface area required a recirculation loop with an external heat exchanger may be used.

Heat transfer coefficients for typical applications.